| 变速方式 | 变频变速 |

|---|---|

| 产品类型 | 全新 |

| 电机功率 | 2.2-55kw |

| 调速范围 | 0-8000r/min |

| 分散轮直径 | 150-500mm |

| 罐容量 | 100--3000L |

| 规格 | GFJ2.2-55kw |

| 升降行程 | 1000-1500MM |

| 适用物料 | 油漆涂料 |

| 速度范围 | 400-1200rpm |

| 外形尺寸 | 1800x1200x2200mm |

| 应用领域 | 油漆涂料化工液体 |

| 整机重量 | 500-3200kg |

| 物料类型 | 固-液 |

| 每次处理量范围 | 出料1000-3000L |

| 分散机类型 | 剪切分散搅拌机 |

| 速度类别 | 无级变速 |

| 品牌 | 龙腾 |

| 型号 | GFJ2.2-55kw |

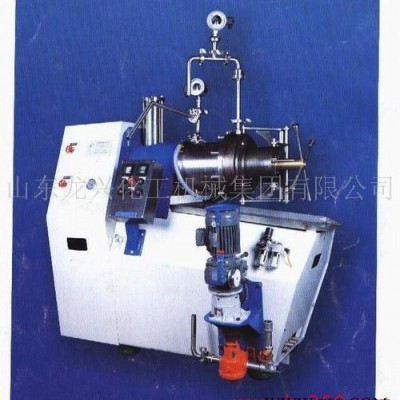

山东龙兴集团是一家油漆涂料生产设备的大型集团化生产企业厂商,几十年来我公司致力于系列机械与液压升降的高速分散搅拌机、蝶式分散搅拌机、真空混合分散搅拌机、移动式混合分散乳化机及管线式分散乳化机,液体立卧式砂磨机及研磨机的开发设计与制造;龙兴集团销售部长原君礼现真诚为您推荐该款多功能高速分散搅拌机,关于多功能高速分散搅拌机技术信息如果不够全面,欢迎您致电和微信(手机同号)咨询!

多功能高速分散搅拌机是用于液体、固体进行搅拌分散、溶解的高效设备,广泛应用涂料、油墨、颜料、胶粘剂等化工产品,该机由液压系统、主传动、搅拌系统、导向机构、电控箱五部分组成,各部分结构紧凑、合理。分散盘型式:平盘锯齿式、三义桨式、碟式等多种形式。设备安全可靠,操作维护简单;生产连续性强,对物料可进行快速分散和溶解,分散效果好,生产效率高,安装简便,适合各种粘度的物料的分散搅拌。

多功能高速分散搅拌机采用无级调速:有电磁调速、变频调速(如用于水性涂料)及防爆变频调速(如用于油性涂料)等多种形式。无级调速功能可以根据不同的工艺阶段需要调整不同的转速,充分满足了各工艺生产过程中不同的工艺要求;液压、机械两种升降形式;分散盘型式:平盘锯齿式、碟式等其它形式;高速分散机通过分散盘上下剧齿的高速运转,能够对物料进行高速的强烈的剪切、撞击、粉碎、分散,达到迅速混合、溶解、分散、细化的功能。针对不同物料的粘度及处理量有不同的功率及型号

高速分散机分单轴和双轴高速分散机,克服了漏油通病,主要是针对不同粘度浆状的液体原料进行粉碎、分散、乳化、混合,通过分散盘上下锯齿的高速运转的新型高效搅拌设备。高速分散搅拌机特点1、强劲的离心力将物料从径向甩入定、转子之间狭窄精密的间隙中,同时受到离心挤压、液层摩擦、液力撞击等综合作用力,物料被初步分散。2、高速分散机的分散盘下方呈层流状态,不同流速的浆料层互相扩散,起到分散作用。高速分散机具有360度回转、无级调速、液压升降等多种功能。可同时配置2-4只容器,液压升降行程1000㎜、360度回转功能能更好的满足一机多用,能够在很短的时间内从一个缸变换到另一个缸进行作业,极大的提高了工作效率,同时也降低了人工劳动强度,

3、分散机物料不断地从径向高速射出,在物料本身和容器壁的阻力下改变流向,与此同时在转子区产生的上、下轴向抽吸力的作用下,又形成上、下两股强烈的翻动紊流。物料经过数次循环**终完成分散过程。

1.Working principles:

The serrated circular blade of the dispersion plate rotates at a high speed so that materials flip up and down intensly in the container, and are impacted and sheared by the blade . As a result, the aggregate is destroyed to rapid dispersion,homogeneous mixing,and fast dissolution.

The machine stirs,dissolves and disperses the liquid or liquid - solid materials at a high speed,to complete the process of solid-liquid dispersion, wetting, depolymerization, and stabilization.

The speed can be arbitrarily adjusted (electromagnetic speed control and frequency speed control), and the speed range is 80-1250 rev / min. The medium speed is used to stir and dissolve, and the high speed to disperse into homogenization. The main motor is the speed control motor.

2.Uses:

It is widely used to produce coatings, dyes, ink, pigments, papermaking, cosmetics, food, resin, adhesive, lotion,

medicine, oil, pesticides, daily chemical and other fields.

3.Performance characteristics:

(1)It makes the slurry into a scroll-like circulation, and produces a strong vortex,then the particles on the surface of the slurry fall into the bottom of the vortex spirally.

(2)Turbulent areas are formed at a distance of 2.5-5mm to the edge of the dispersion plate, then the slurry and particles are sheared and shocked strongly;

(3)With the upper and the lower beams formed outside the region , the slurry is fully cycled and flipped;

(4)The laminar area is formed beneath the dispersion plate, and different rates of slurries spread mutually;

(5)The 270-degree rotation of the body can better meet the needs of multi-purposes .It can be transformed to work from one cylinder to another in a very short time, which greatly increases the work efficiency.

4.Category :

There are mechanical lifts and hydraulic lifts. There are electromagnetic speed control motor, frequency control mortor (such as for water-based paint), and explosion-proof frequency control motor(such as for oil-based paint).

5.Notes:

Our company is able to undertake the non-standard customization according to the customer’s specific requirements. (It needs the customers to provide the size of their drawings.)

友情提示:

选择一种好设备的关键除了质量、售后、和信誉之外,还必须要满足自身对设备的要求,山东龙兴化工集团拥有专业的技术工程师不断进行技术改革与市场相结合,本厂生产的产品规格品种齐全。可来图定制也可根据客户需求代为设计制造,销售部长原君礼欢迎您的垂询和惠顾!