| 材质 | 铸铁 |

|---|---|

| 功率 | 22 |

| 级数 | 单级 |

| 性能 | 不阻塞 |

| 扬程 | 113 |

| 转速 | 2900 |

| 品牌 | 长沙东方 |

| 型号 | ISG50-315(I)C |

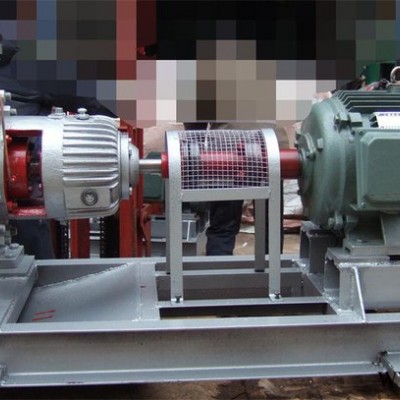

管道泵ISG50-315(I)C 单级泵 叶轮 泵壳 铸铁材质 长沙供应

工作条件

??1、吸入压力≤1.0MPa,或泵系统高工作压力≤1.6MPa,即泵吸入口压力+泵扬程≤1.6MPa,泵静压试验压力为2.5MPa,订货时请注明系统工作压力。泵系统工作压力大于1.6MPa时应在订货时另行提出,以便在制造时泵的过流部分和联接部分采用铸钢材料。

??2、环境温度<40℃,相对湿度<95%。

??3、所输送介质中固体颗粒体积含量不超过单位体积的0.1%,粒度<0.1mm。

??注:如使用介质为带有细小颗粒,请在订货时说明,以便厂家采用耐磨式机械密封。

主要用途

??1、ISG型立式管道离心泵,供输送清水及物理化学性质类似于清水的其他液体之用,适用于工业和城市给排水、高层建筑增压送水、园林喷灌、消防增压、远距离输送、暖通制冷循环、浴室等冷暖水循环增压及设备配套,使用温度T<80℃。

??2、IRG(GRG)型立式热水(高温)循环泵广泛适用于:能源、冶金、化工、纺织、造纸,以及宾馆饭店等锅炉高温热水增压循环输送及城市采用暖系统循环用泵,IRG型使用温度T<120℃,珀GRG型使用温度T<240℃。

??3、IHG型立式管道化工泵,供输送不含固体颗粒,具有腐蚀性,粘度类似于水的液体,适用于石油、化工、冶金、电力、造纸、食品制药和合成纤维等部门,使用温度为20℃~+120℃。

??4、YG型立式管道油泵,供输送汽油、煤油、柴油等石油产品,被输送介质温度为-20℃~+120℃。

| 型号 | 流量 | 扬程 | 效率 | 转速 | 电机功率 | 必需汽蚀余量 | 重量 | |

| m3/h | L/s | m | % | r/min | kw | m | kg | |

| 50-100 | 8.8 | 2.44 | 13.6 | 55 | 2900 | 1.1 | 2.3 | 36 |

| 12.5 | 3.47 | 12.5 | 62 | |||||

| 16.3 | 4.53 | 11.3 | 60 | |||||

| 50-100A | 8 | 2.22 | 11 | 60 | 2900 | 0.75 | 2.3 | 35 |

| 11 | 3.05 | 10 | ||||||

| 14.5 | 4.03 | 9 | ||||||

| 50-125 | 8.8 | 2.44 | 21.5 | 49 | 2900 | 1.5 | 2.3 | 43 |

| 12.5 | 3.47 | 20 | 58 | |||||

| 16.3 | 4.53 | 17.8 | 57 | |||||

| 50-125A | 8 | 2.22 | 17 | 57 | 2900 | 1.1 | 2.3 | 38 |

| 11 | 3.05 | 16 | ||||||

| 14.5 | 4.03 | 14 | ||||||

| 50-160 | 8.8 | 2.44 | 33 | 45 | 2900 | 3 | 2.3 | 59 |

| 12.5 | 3.47 | 32 | 52 | |||||

| 16.3 | 4.53 | 30 | 51 | |||||

| 50-160A | 8.2 | 2.28 | 29 | 44 | 2900 | 2.2 | 2.3 | 51 |

| 11.7 | 3.25 | 28 | 51 | |||||

| 15.2 | 4.22 | 26 | 50 | |||||

| 50-160B | 7.3 | 2.38 | 23 | 50 | 2900 | 1.5 | 2.3 | 47 |

| 10.4 | 2.89 | 22 | ||||||

| 13.5 | 3.75 | 20.5 | ||||||

| 50-200 | 8.8 | 2.44 | 52 | 38 | 2900 | 5.5 | 2.3 | 101 |

| 12.5 | 3.47 | 50 | 46 | |||||

| 16.3 | 4.53 | 48 | 46 | |||||

| 50-200A | 8.3 | 2.31 | 45.8 | 37 | 2900 | 4 | 2.3 | 80 |

| 11.7 | 3.25 | 44 | 45 | |||||

| 15.3 | 4.25 | 42 | 45 | |||||

| 50-200B | 7.5 | 2.08 | 37 | 44 | 2900 | 3 | 2.3 | 68 |

| 10.6 | 2.94 | 36 | ||||||

| 13.8 | 3.83 | 34 | ||||||

| 50-250 | 8.8 | 2.44 | 82 | 29 | 2900 | 11 | 2.3 | 160 |

| 12.5 | 3.47 | 80 | 38 | |||||

| 16.3 | 4.53 | 77.5 | 40 | |||||

| 50-250A | 8.2 | 2.28 | 71.5 | 38 | 2900 | 7.5 | 2.3 | 115 |

| 11.6 | 3.22 | 70 | ||||||

| 15.2 | 4.22 | 68 | ||||||

| 50-250B | 7.6 | 2.11 | 61.4 | 37 | 2900 | 7.5 | 2.3 | 114 |

| 10.8 | 3 | 60 | ||||||

| 14 | 3.89 | 58 | ||||||

| 50-250C | 7.1 | 1.97 | 53.2 | 36 | 2900 | 5.5 | 2.3 | 108 |

| 10 | .2.78 | 52 | ||||||

| 13.1 | 3.64 | 50.4 | ||||||

| 50-100(I) | 17.5 | 4.86 | 13.7 | 67 | 2900 | 1.5 | 2.5 | 41 |

| 25 | 6.94 | 12.5 | 69 | |||||

| 32.5 | 9.03 | 10.5 | 69 | |||||

| 50-100(I)A | 15.6 | 4.3 | 11 | 65 | 2900 | 1.1 | 2.5 | 36 |

| 22.3 | 6.19 | 10 | 67 | |||||

| 29 | 8.1 | 8.4 | 68 | |||||

| 50-125(I) | 17.5 | 4.86 | 21.5 | 60 | 2900 | 3 | 2.5 | 56 |

| 25 | 6.94 | 20 | 68 | |||||

| 32.5 | 9.03 | 18 | 67 | |||||

| 50-125(I)A | 15.6 | 4.33 | 17 | 58 | 2900 | 2.2 | 2.5 | 48 |

| 22.3 | 6.19 | 16 | 66 | |||||

| 29 | 8.1 | 13.6 | 65 | |||||

| 50-160(I) | 17.5 | 4.68 | 34.4 | 54 | 2900 | 4 | 2.5 | 72 |

| 25 | 6.94 | 32 | 63 | |||||

| 32.5 | 9.03 | 27.5 | 60 | |||||

| 50-160(I)A | 16.4 | 4.56 | 30 | 54 | 2900 | 4 | 2.5 | 71 |

| 23.4 | 6.5 | 28 | 62 | |||||

| 30.4 | 8.44 | 24 | 59 | |||||

| 50-160(I)B | 15 | 4.17 | 26 | 58 | 2900 | 3 | 2.5 | 59 |

| 21.6 | 6 | 24 | ||||||

| 28 | 7.78 | 20.6 | ||||||

| 50-200(I) | 17.5 | 4.86 | 52.7 | 49 | 2900 | 7.5 | 2.5 | 108 |

| 25 | 6.94 | 50 | 58 | |||||

| 32.5 | 9.03 | 45.5 | 59 | |||||

| 50-200(I)A | 16.4 | 4.56 | 46.4 | 48 | 2900 | 7.5 | 2.5 | 107 |

| 23.5 | 6.53 | 44 | 57 | |||||

| 30.5 | 8.47 | 40 | 58 | |||||

| 50-200(I)B | 15.2 | 4.22 | 40 | 55 | 2900 | 5.5 | 2.5 | 100 |

| 21.8 | 6.06 | 38 | ||||||

| 28.3 | 7.86 | 34.5 | ||||||

| 50-250(I) | 17.5 | 4.86 | 82 | 39 | 2900 | 15 | 2.5 | 175 |

| 25 | 6.94 | 80 | 50 | |||||

| 32.5 | 9.03 | 76.5 | 52 | |||||

| 50-250(I)A | 16.4 | 4.56 | 71.5 | 39 | 2900 | 11 | 2.5 | 165 |

| 23.4 | 6.5 | 70 | 50 | |||||

| 30.5 | 8.47 | 67 | 52 | |||||

| 50-250(I)B | 15 | 4.17 | 61 | 38 | 2900 | 11 | 2.5 | 165 |

| 21.6 | 6 | 60 | 49 | |||||

| 28 | 7.78 | 57.4 | 54 | |||||

| 50-315(I) | 17.5 | 4.86 | 128 | 30 | 2900 | 30 | 2.5 | 310 |

| 25 | 6.94 | 125 | 40 | |||||

| 32.5 | 9.03 | 122 | 44 | |||||

| 50-315(I)A | 16.6 | 4.61 | 115 | 30 | 2900 | 22 | 2.5 | 245 |

| 23.7 | 6.58 | 113 | 40 | |||||

| 31 | 8.6 | 110 | 44 | |||||

| 50-315(I)B | 15.7 | 4.36 | 103 | 39 | 2900 | 18.5 | 2.5 | 215 |

| 22.5 | 6.23 | 101 | ||||||

| 29.2 | 8 | 98 | ||||||

| 50-315(I)C | 14.4 | 4 | 86 | 38 | 2900 | 15 | 2.5 | 195 |

| 20.6 | 5.72 | 85 | ||||||

| 26.8 | 7.44 | 83 | ||||||